Sources: Federal Highway Administration; National Ready Mixed Concrete Association, Alexandria, Va.: CP staff

The Federal Highway Administration’s new TechNote on Portland Limestone Cement (FHWA-HRT-23-104) provides state highway agencies, contractors and concrete practitioners information enabling broader adoption of a blended binder to which cement plants across North America are migrating. The 12-page document reviews the history of PLC in the U.S.; chemical and physical requirements for a binder combining portland cement + 5-15 percent interground limestone, per ASTM C595/AASHTO M240 Standard Specification for Blended Hydraulic Cement; and, carbon dioxide emissions reduction attributable to PLC finishing.

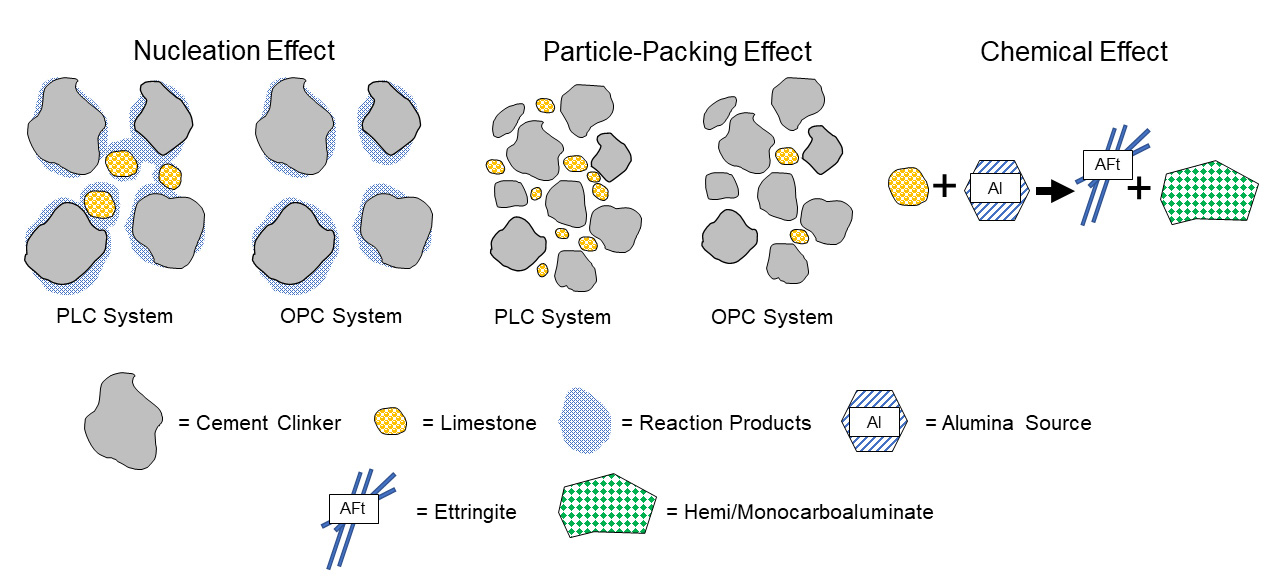

TechNote authors examine the engineering principles of nucleation, particle packing and chemical effects of PLC, along with the binder’s impact on fresh and hardened concrete properties, including volume stability and durability from various research reports. They also outline potential changes to concrete performance and suggest best practices to evaluate and test PLC in mixtures. They conclude with briefs from transportation project case studies on successful use of the blended binder.

PORTLAND LIMESTONE CEMENT: MIXTURE MECHANICS